In this blog, Amit Sachdeva looks at how advances in IoT and AI are set to revolutionise supply chain management and how goods get from A to B.

What can we learn from our calamitous canteen? That a chain is no stronger than its weakest link, whether it’s made of restaurant staff or a combination of producers, warehouses, logistics companies and vendors. It only needs one part of the sequence to fail or underperform and the whole thing can be jeopardised.

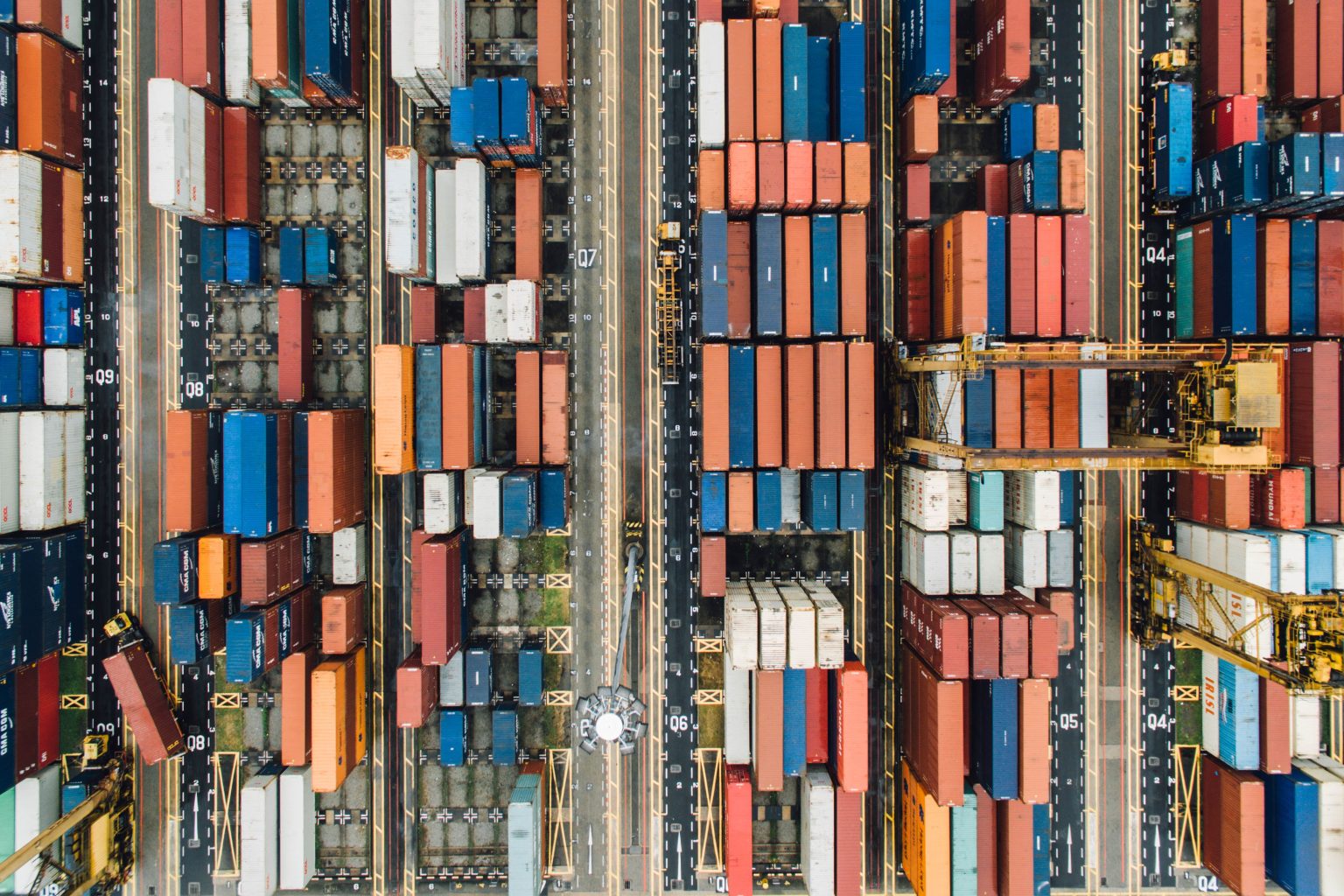

Logistics’ transformation journey

With the rise of digital transformation, shipping companies, freight forwarders, road hauliers and related supply chain companies are increasingly using data to inform and communicate how they manage their businesses.

“When transporting anything from A to B, the more you know about the process from start to finish the better.”

It allows companies to improve their operations in multiple areas, including visibility, planning and efficiency, and customer service. More sophisticated connectivity enables access to real-time information on the status of shipments and inventories and allows businesses to source the most cost-efficient transport options and plan the best routes.

In the past, once a shipment had started on its journey, opportunities to track its condition and progress were limited, with cargoes spending the majority of their time in blind-spots, but with the capabilities offered by connected vehicles and sensors on pallets and containers, both customers and suppliers can keep track of exactly where their consignments are at every step. Especially in the context of Just-in-Time deliveries, real-time access to accurate information is paramount.

“Being able to tell your customers exactly where your products have been and when, right down to the minute, could also become a real point of differentiation between one business and another.”

Not just getting from A to B

With the rise of IoT, logistics companies can also provide insight into the condition of cargoes throughout the journey, ensuring that their integrity is maintained and helping to avoid any nasty surprises on arrival. With every step of the chain being monitored on a granular level and in real time, this can help to limit waste, optimise inventories, reduce operating costs and maximise profits. 5G will only make this more accessible for more businesses and increase the number of vehicles and hubs in the wider IoT ecosystem that can communicate with each other.

Additionally, as more companies embrace the opportunities offered by technologies such as artificial intelligence (AI) and machine learning, many supply chain processes will be automated further, and demand will be calculated without any human involvement at all. Amazon owns a patent on predictive shipping, which will use analytics to anticipate demand and start the process before items have even been ordered.

“Products will be shipped to distribution centres in regions where they’re expected to be needed and diverted to specific areas when the orders come in, shortening the overall fulfilment time significantly.”

So, in the not-too-distant future, the shipping process will be able to predict demand in advance and start products on their journey in anticipation.

Increased automation of the supply chain will also see the proliferation of robots, particularly in warehouses where loading and unloading can be done more quickly and with less opportunity for errors. According to Deloitte, 88% of supply chain professionals think that robotics and automation will allow organisations to manage risk and improve predictability. Eventually, this will also extend to the actual driving, as autonomous trucks begin to replace traditional haulage vehicles, with AI drivers that won’t be constrained by a maximum number of hours they can spend behind the wheel.

Increased automation of the supply chain will also see the proliferation of robots, particularly in warehouses where loading and unloading can be done more quickly and with less opportunity for errors. According to Deloitte, 88% of supply chain professionals think that robotics and automation will allow organisations to manage risk and improve predictability. Eventually, this will also extend to the actual driving, as autonomous trucks begin to replace traditional haulage vehicles, with AI drivers that won’t be constrained by a maximum number of hours they can spend behind the wheel.

With the logistics industry also likely to come under increased scrutiny for its impact on the environment, digital transformation initiatives can help companies to minimise their carbon footprint by streamlining their processes.

These developments invariably involve many partners and various different technologies. All these innovations will be underpinned by reliable, borderless connectivity through a best-in-class global infrastructure, which will enable real-time access to data-enabled insights end-to-end. The impact it will have on user experience, supply chain agility and overall efficiencies in the logistics sector cannot be underestimated.

If you’re interested in other innovations affecting the vehicular industry, have a look at our blog exploring advances being made across the connected car lifecycle.